Illumimate

OBJECTIVE // To find a way to feel more connected to my family and loved ones that live far away from me.

Illumimate

BACKGROUND // Though my family has always encouraged me to follow my dreams wherever that might take me, it hasn’t made it easy to feel their presence in my life. I can text and call them, but that is a scheduled and active interaction; I found that there was an opportunity to passive feel their motion while I go about my day. To fill this void, I decided to try to build a motion sensor activated light that you place on your counter and when you walk by, it illuminates the partner lamp your family member’s household. The organic pattern of the light helps you feel their activity in your home.

SKETCHES & IDEATION // My processes started with some quick sketches to try to understand what the form and aesthetic might look like. At this stage the functionality wasn’t quite defined and there were few constraints. I was trying to envision a diverse selection of ideas for how this general motion sensor light might look.

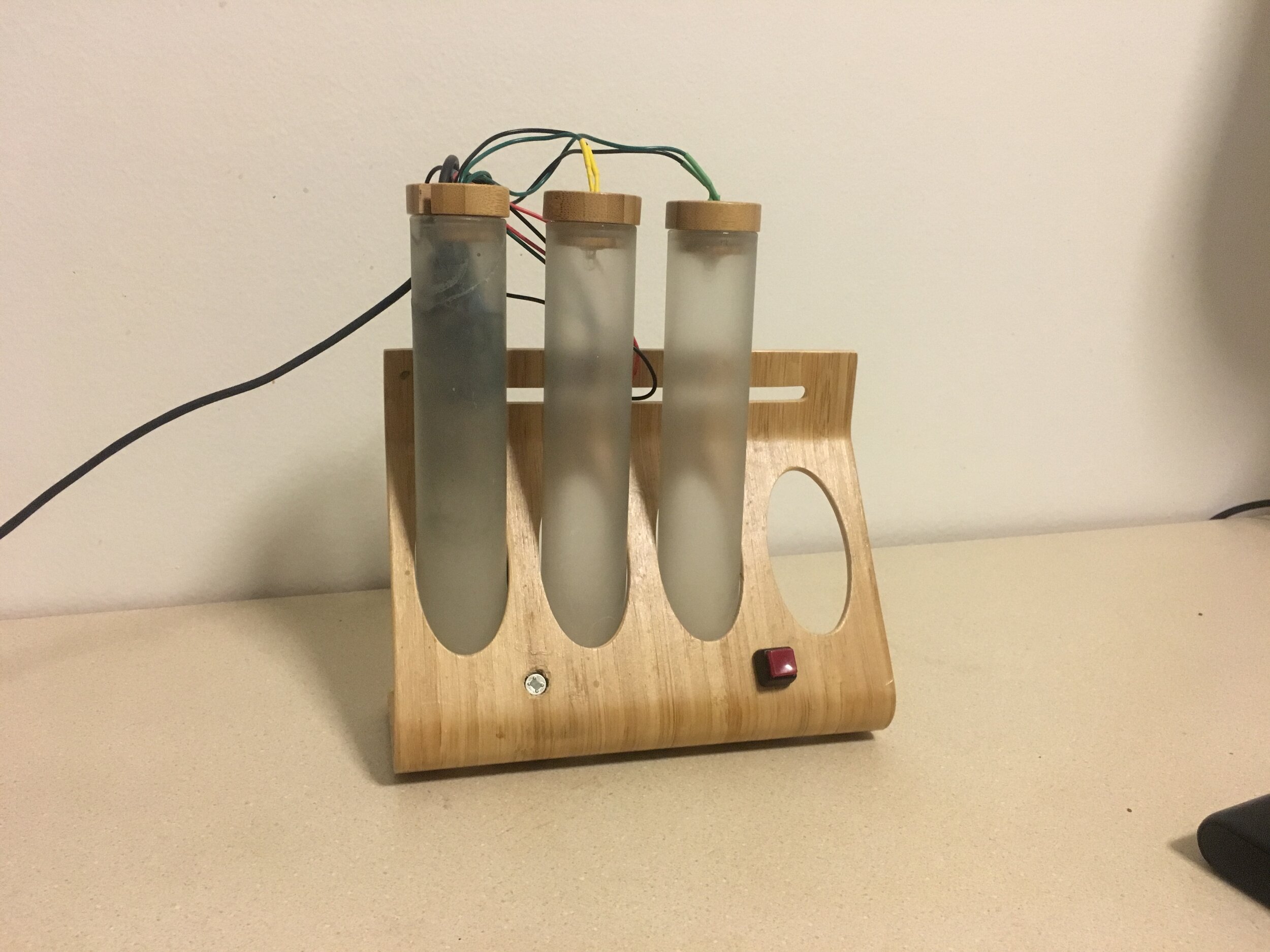

EARLY PROTOTYPES // Over the last couple years, I had attempted to build a prototype of this idea a couple times. The first time involved some modified IKEA spices holders. The next was looking at whether I could turn it into a clock. I explored some different motion sensors, but never really created something beautiful enough to warrant pursuing further.

RAPID PROTOTOYPES // One of the things I quickly realized is that if this device is going to live prominently on your countertop, it is going to have to have a high aesthetic value as the counterspace is at a premium. This was my primary focus with my early prototypes as I wanted to figure out a form that would make a compelling artistic item to live on your counter. A big part of the technical challenge was ensuring that the light was properly diffused to give a solid illumination around the perimeter without any hotspots, so a part of my rapid prototypes were to explore the illumination techniques with some breadboard electronics.

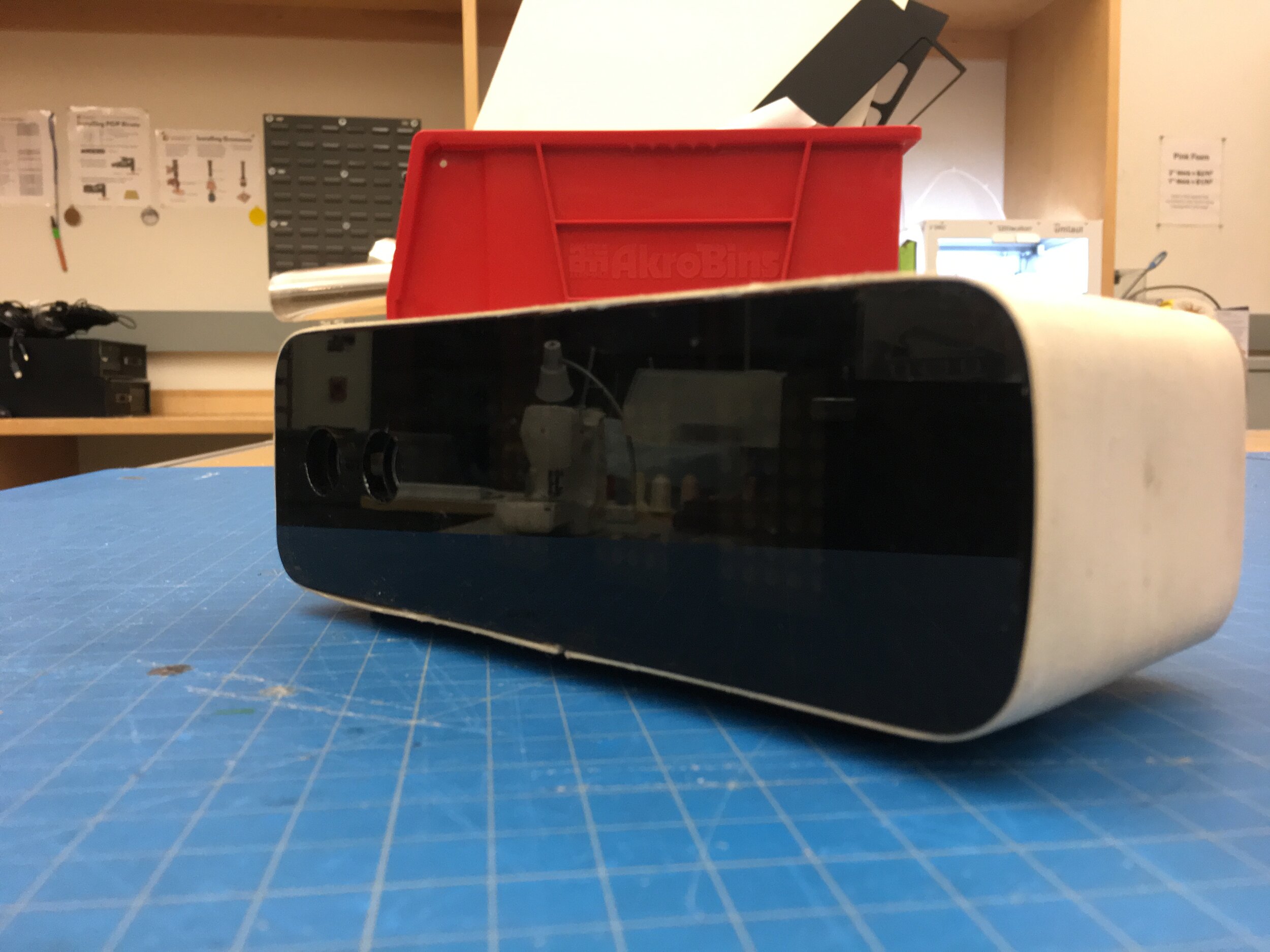

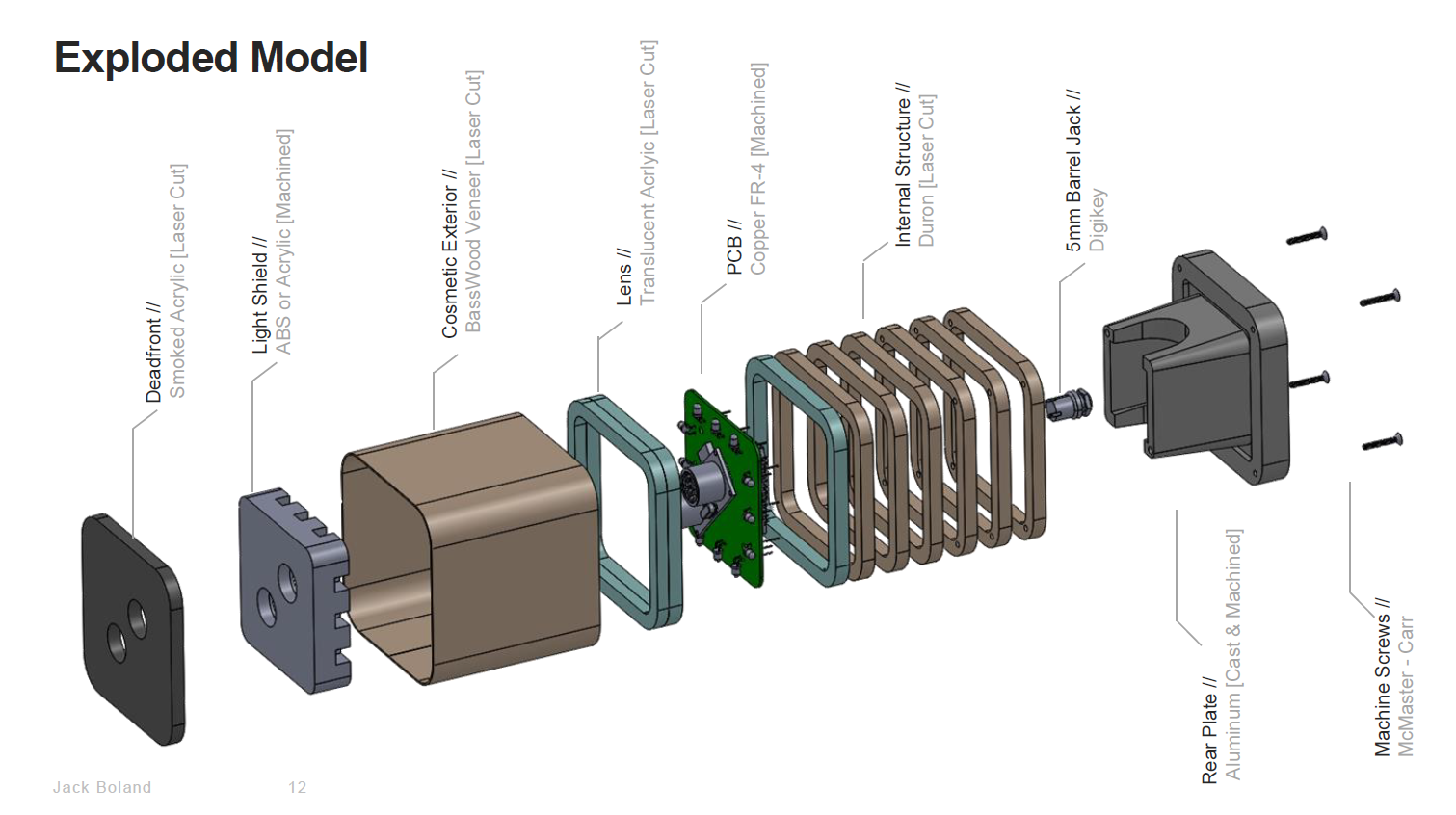

ALPHA PROTOTYPE // After establishing the form and functionality that I wanted to pursue, I jumped into CAD and started flushing out the details of how I was going to make the device. I decided to cast the base out of aluminum using the foundry in the Product Realization Lab. Then used a FDM plastic structure with a series of stacked acrylic plates to act as the LED diffusers and deadfront. On the exterior is a thin wood veneer the gives it a warmer, quality appearance and feel.

SAND CASTING //

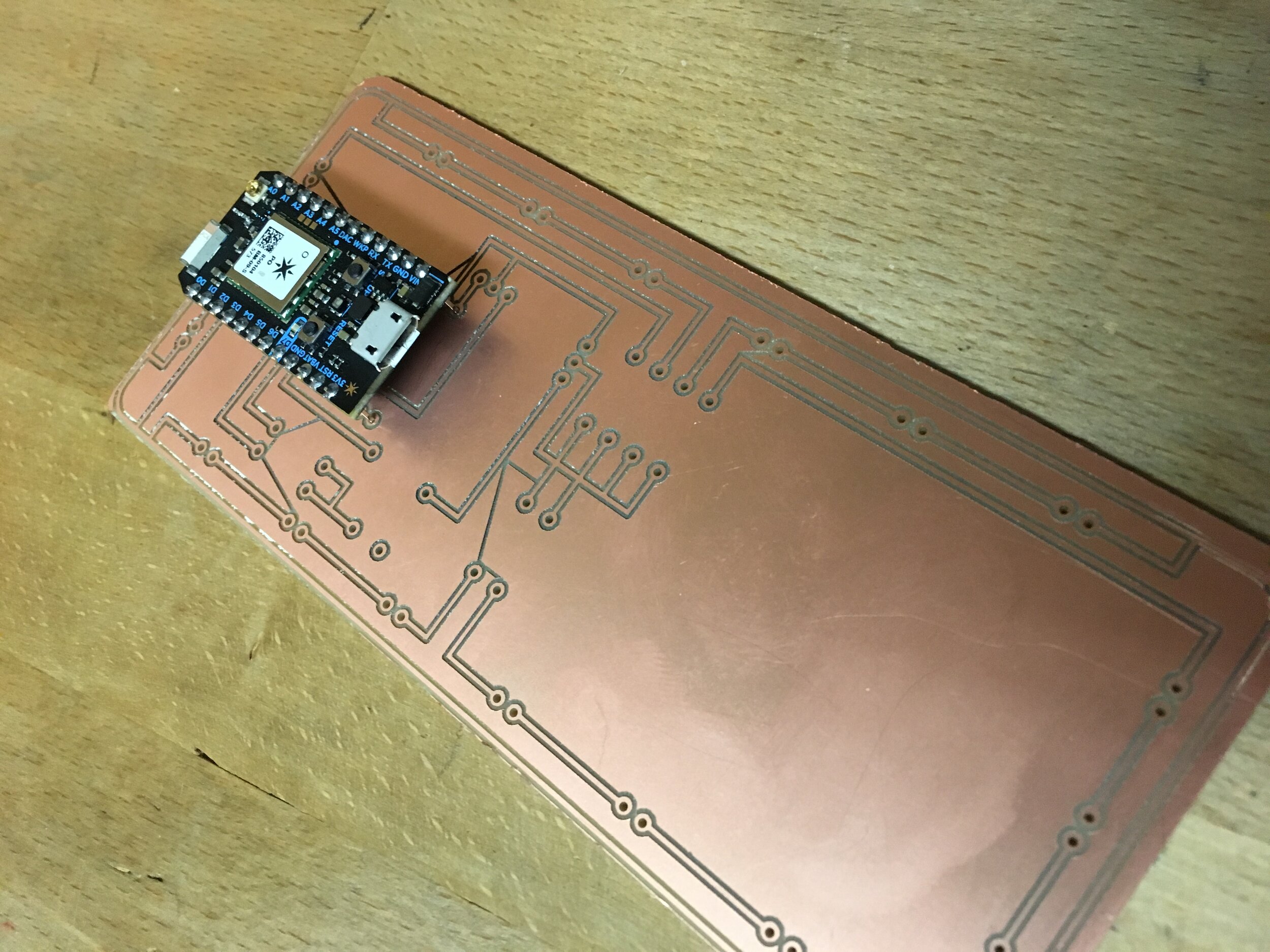

PCB MILLING // I also decided that it was a great opportunity to use the PCB mill that I built to create the circuit board for the LEDs. Using Solidworks to generate a PCB, since the circuitry was so simple, I used a CAM software to create the tool paths and then a GCode sending software to communicate with the mill.

Once I had the PCB built up, I was ready to start testing out the coding. I wrote some firmware that allowed both devices to connect to a cloud platform and talk to one another. Unfortunately, because of Stanford’s network security, I had to use my phone as a hot spot in order to produce a consistent network.